Why Do Contractors Choose These Access Solutions Again and Again?

Posted by Access Doors and Panels on 16th Dec 2025

Contractors choose flood-tight access solutions repeatedly because they offer proven, long-term protection against water damage and operational failure in high-risk environments.

Water-prone areas like pump stations, wastewater facilities, and underground vaults face the risk of leaks and system damage.

When faced with flooding or standing water, standard hatches simply don't provide the level of protection needed. This can lead to operational downtime and expensive repairs.

Flood-tight floor hatches are specifically engineered to resist hydrostatic pressure. This article explains how their watertight seal works and where they are most effective, proving why civil engineers and contractors trust them.

Why Do Contractors Keep Choosing Flood-Tight Access Doors?

Contractors choose flood-tight floor access hatches because they have a proven track record of preventing water intrusion in real-world conditions. Their reliability during flood events has earned long-term trust in critical infrastructure projects.

Consistently Delivers Waterproof Performance

Flood-resistant access panels are purpose-built to guarantee waterproof sealing even under extreme conditions. Unlike standard panels, these high-quality waterproof access doors are proven to resist hydrostatic pressure, which is the force exerted by water at rest.

When a critical utility vault or pump station is submerged, contractors need to know the access door will hold every single time. This proven resistance under hydrostatic pressure in testing labs and the real world helps here.

Reduces Downtime and Risk

In environments like wastewater treatment and stormwater systems, reliability is a necessity. Every minute of operational downtime can be costly and lead to environmental or public health crises.

By installing a flood-tight door, contractors reduce the risk of water intrusion that could damage sensitive equipment or cause system failure.

This preventive approach to asset protection is invaluable. It makes the decision to opt for a sealed solution easy for those focused on minimizing long-term risk.

Ensures Compliance and Safety Standards

Choosing a specialized access solution also instills confidence in compliance and safety standards. Infrastructure projects, particularly those related to water management, face stringent regulations by bodies such as the Federal Flood Risk Management Standard (FFRMS).

These heavy-duty floor hatches are built to withstand high-traffic industrial environments. They often carry ratings that meet or exceed the requirements of various safety and regulatory bodies.

Specifying a product with a proven flood-tight performance ensures the project meets the mark, giving contractors peace of mind during inspections and operational handover.

Saves Long-Term Costs

While the initial cost of a flood-tight access door may be higher than that of a standard panel, the long-term savings are undeniable.

For one, the hatch pays for itself many times over by preventing major water damage to expensive underground equipment. It also significantly reduces long-term maintenance and repair costs associated with water damage, ultimately making it a more economical choice.

Don't wait for the next flood event to test your access solutions. Request a quote now and get recommendations for flood-tight access doors with proven performance and long-term savings.

How Does a True Flood-Tight Seal Work?

A true flood-tight seal uses high-quality squeezed rubber to block water. It creates a complete barrier strong enough to resist the tremendous pushing force of floodwater.

Here is the simple breakdown. While great for regular use, standard floor hatches have weaker seals that may not withstand hydrostatic pressure. This force can easily lift, bend, or push water past the seal, flooding the space below.

Flood-tight solutions use a heavy-duty neoprene gasket (a specialized, resilient rubber seal). This gasket sits in a channel between the frame and the cover. When a crew closes the hatch, they secure it by tightening specialized stainless-steel bolts around the perimeter. This action creates uniform pressure that squeezes the resilient gasket tightly into any gap.

This compression seal forces the rubber to fill every space, making the barrier impenetrable. The design is so sturdy that the hatch remains watertight even when fully submerged, fighting the upward hydrostatic pressure that would cause a standard cover to fail.

Other Features That Keep the Hatch Flood Tight

- Welded, Bolted Construction: The frame is fully welded and bolted to the structure. This intense structural integrity prevents the frame from twisting or warping under the massive upward force of hydrostatic pressure, which also helps keep the seal intact.

- Corrosion-Resistant Hardware: All hinges, bolts, and locking components are stainless steel. This is vital because if the metal parts rust or seize, the hatch can't be closed tightly enough to activate the watertight seal. Stainless steel ensures the hatch can be reliably operated and sealed for decades.

- Heavy-Duty Cover: The cover is built like a structural component to support heavy traffic (like vehicles or equipment) without bending. A rigid cover is essential because deflection could temporarily break the compression seal.

Related: How to Keep Your Commercial Building's Foundation Flood-Free

Where Are Flood-Tight Hatches Most Effective?

Flood-tight floor hatches are the required standard in high-risk areas where water or moisture is an ongoing threat. They are essential for protecting equipment, reducing environmental hazards, and preventing facility failure.

- Water and Sewer Facilities: These sites are frequently exposed to flooding, standing water, and chemicals, making a guaranteed seal non-negotiable.

- Building Protection: They are crucial for underground utilities, basements, and building sublevels that house vital IT or electrical services.

- Coastal and Low-Lying Sites: Any infrastructure prone to heavy rain, river overflow, or coastal storm surges relies on the sealed security of a flood-resistant access door to ensure long-term resilience.

- Transportation and Transit Systems: Used in subway stations, train tunnels, airport service areas, and highway underpasses where water accumulation or storm runoff poses high operational risks.

- Industrial and Manufacturing Facilities: Flood-tight hatches are essential in plants with washdown environments (e.g., food processing, chemical facilities) or areas where unexpected leaks or process water could compromise production equipment.

Related: 5 Steps to Handle Flooding on Your Commercial Building

What Makes the BA-FTFD Reliable in Harsh, Wet Environments?

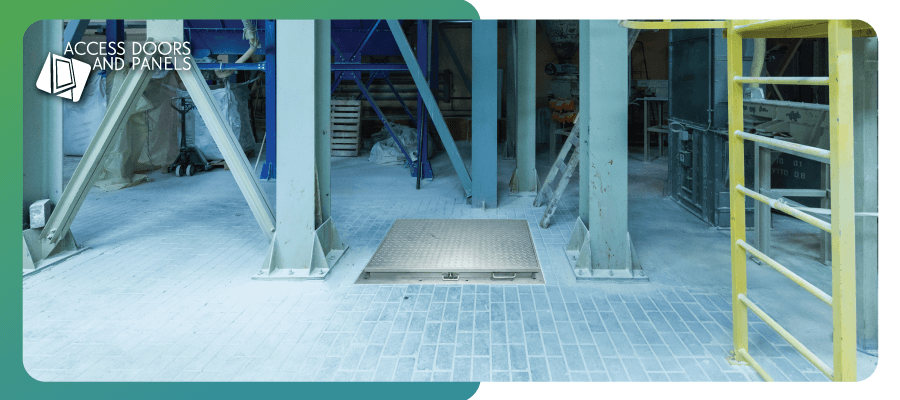

The BA-FTFD Flood Tight Floor Hatch is a top example of a floor hatch that combines heavy-duty construction with high-quality seals that fight water intrusion. These distinct features are why it's such a popular product.

- The floor hatch features a 3/8", U-shaped neoprene gasket perimeter and a stainless-steel pressure lock system that ensures no water intrusion during flooding.

- The diamond plate door panel is reinforced for a 625 pounds/sq ft. live load, and can withstand up to 10 ft. head of water.

- Stainless steel hinges and hardware to ensure corrosion resistance despite constant water exposure.

- An automatic hold-open arm with a grip that allows the door to open at 90 degrees, keeping with the OSHA standards for confined space access.

- Stainless steel compression springs that provide lift assistance, and the option for electrical actuators operated by a wall-mounted push button switch, and a remote control.

Can’t find the size you’re looking for? Contact our technical team to discuss custom sizes and configurations for flood-prone sites.

Frequently Asked Questions About Flood-Tight Hatches

1. What does ‘hydrostatic pressure’ mean for my access solution?

Hydrostatic pressure is the pressure exerted by water at rest. For access hatches, it refers to the upward force of standing or flood water pushing against the underside of the cover. Standard hatches are not built to resist this force, which is why flood-tight hatches are ideal.

2. How often should the gasket be checked?

In frequently flooded environments, the rule of thumb is to conduct a full gasket inspection at least annually. Another recommended period is after any major flooding event has occurred. It is necessary to check for signs of compression loss or damage.

3. Are flood-tight hatches suitable for chemical exposure?

Yes. Quality flood-tight hatches, particularly those made from reinforced aluminum and stainless-steel hardware, have high corrosion resistance. This makes them great for wastewater treatment plants and chemical storage areas.

Conclusion

Contractors continue to choose flood-tight floor hatches because they're dependable in areas where water intrusion can stop operations and cause severe damage. With a watertight, compressed seal and corrosion-resistant construction, these hatches help maintain system integrity, prevent costly repairs, and support regulatory compliance.

They reduce downtime and safeguard infrastructure by stopping water before it becomes problematic. Flood-tight hatches remain a trusted, long-term solution for projects in pump stations, basements, low-lying zones, or coastal developments.

Ready to protect your infrastructure with a flood-tight solution you can trust? Contact us today to discuss your project and get expert guidance—or call +1-888-327-5471 now.